SUBCHAPTER 02D - AIR POLLUTION CONTROL REQUIREMENTS

SECTION .0100 - DEFINITIONS AND REFERENCES

15A NCAC 02D .0101 DEFINITIONS

The definition of any word or phrase used in Rules of this Subchapter is the same as given in Article 21, G.S. 143, as amended. The following words and phrases, which are not defined in the article, have the following meaning:

(1) "Act" means Article 21, G.S. 143, entitled "Water and Air Resources."

(2) "Administrator" means, when it appears in any Code of Federal Regulation incorporated by reference in this Subchapter, the Director of the Division of Air Quality unless:

(a) a specific rule in this Subchapter specifies otherwise; or

(b) the U.S. Environmental Protection Agency, in a delegation or approval, states that a specific authority of the Administrator of the Environmental Protection Agency is not included in such a delegation or approval.

(3) "Air pollutant" means an air pollution agent or combination of such agents, including any physical, chemical, biological, or radioactive substance or matter emitted into or otherwise entering the ambient air.

(4) "Ambient air" means that portion of the atmosphere outside buildings or other enclosed structures, stacks, or ducts and that surrounds human, animal, or plant life or property.

(5) "Approved" means approved by the Director of the Division of Air Quality according to these Rules.

(6) "Capture system" means the equipment including hoods, ducts, and fans, used to contain, capture, or transport a pollutant to a control device.

(7) "CFR" means the Code of Federal Regulations.

(8) "Combustible material" means any substance that, when ignited, will burn in air.

(9) "Construction" means change in method of operation or any physical change, including on-site fabrication, erection, installation, replacement, demolition, or modification of a source, that results in a change in emissions or affects the compliance of a facility.

(10) "Control device" means equipment, including fume incinerator, adsorber, absorber, scrubber, filter media, cyclone, and electrostatic precipitator, used to destroy or remove an air pollutant before discharge to the ambient air.

(11) "Day" means a 24-hour period beginning at midnight.

(12) "Director" means the Director of the Division of Air Quality, unless otherwise specified.

(13) "Division" means Division of Air Quality.

(14) "Dustfall" means particulate matter that settles out of the air. Dustfall shall be expressed in units of grams per square meter per 30-day period.

(15) "Emission" means the release or discharge, whether directly or indirectly, of any air pollutant into the ambient air from any source.

(16) "Facility" means all of the pollutant-emitting activities, except transportation facilities, that are located on one or more adjacent properties under common control.

(17) "FR" means the Federal Register.

(18) "Fugitive emission" means those emissions that could not reasonably pass through a stack, chimney, vent, or other functionally-equivalent opening.

(19) "Fuel burning equipment" means equipment whose primary purpose is the production of energy or power from the combustion of any fuel. Uses of the equipment include heating water, generating or circulating steam, heating air as in a warm air furnace, or furnishing process heat by transferring energy by fluids or through process vessel walls.

(20) "Garbage" means any animal or vegetable waste resulting from the handling, preparation, cooking, or serving of food.

(21) "Incinerator" means a device designed to burn solid, liquid, or gaseous waste material.

(22) "Opacity" means that property of a substance tending to obscure vision and is measured as percent obscuration.

(23) "Open burning" means any fire whose products of combustion are emitted directly into the outdoor atmosphere without passing through a stack or chimney, approved incinerator, or other similar device.

(24) "Owner or operator" means any person who owns, leases, operates, controls, or supervises a facility, source, or air pollution control equipment.

(25) "Particulate matter" means any material except uncombined water that exists in a finely divided form as a liquid or solid at standard conditions.

(26) "Particulate matter emissions" means all finely divided solid or liquid material, other than uncombined water, emitted to the ambient air as measured by methods specified in this Subchapter.

(27) "Permitted" means any source subject to a permit under this Subchapter or 15A NCAC 02Q.

(28) "Person" as defined in G.S. 143-212 includes any individual, partnership, co-partnership, firm, company, corporation, association, joint stock company, trust, estate, political subdivision, or any other legal entity, or its legal representative, agent, or assigns.

(29) "PM10" means particulate matter with an aerodynamic diameter less than or equal to a nominal 10 micrometers as measured by methods specified in this Subchapter.

(30) "PM10 emissions" means finely divided solid or liquid material, with an aerodynamic diameter less than or equal to a nominal 10 micrometers emitted to the ambient air as measured by methods specified in this Subchapter.

(31) "PM2.5" means particulate matter with an aerodynamic diameter less than or equal to a nominal 2.5 micrometers as measured by methods specified in this Subchapter.

(32) "Refuse" means any garbage, rubbish, or trade waste.

(33) "Rubbish" means solid or liquid wastes from residences, commercial establishments, or institutions.

(34) "Rural area" means an area that is devoted to the following uses: agriculture, recreation, wildlife management, state park, or any area of natural cover.

(35) "Salvage operation" means any business, trade, or industry engaged in whole or in part in salvaging or reclaiming any product or material, including metal, chemicals, motor vehicles, shipping containers, or drums.

(36) "Smoke" means small gas-borne particles resulting from incomplete combustion, consisting predominantly of carbon, ash, and other burned or unburned residue of combustible materials that form a visible plume.

(37) "Source" means any stationary article, machine, process equipment, or other contrivance, singly or in combination, or any tank-truck, trailer, or railroad tank car, from which air pollutants emanate or are emitted, either directly or indirectly.

(38) "Sulfur oxides" means sulfur dioxide, sulfur trioxide, their acids, and the salts of their acids.

(39) "Transportation facility" means a complex source as defined in G.S. 143‑213(22).

(40) "Total suspended particulate" means any finely divided solid or liquid material, except water in uncombined form, that is or has been airborne as measured by methods specified in this Subchapter.

(41) "Trade wastes" means all solid, liquid, or gaseous waste materials or rubbish resulting from combustion, salvage operations, building operations, or the operation of any business, trade, or industry including plastic products, paper, wood, glass, metal, paint, grease, oil and other petroleum products, chemicals, and ashes.

(42) "ug" or "µg" means micrograms.

History Note: Authority G.S. 143‑213; 143‑215.3(a)(1);

Eff. June 1, 1976;

Amended Eff. December 1, 1989; July 1, 1988; July 1, 1984;

Temporary Amendment Eff. March 8, 1994 for a period of 180 days or until the permanent rule becomes effective, whichever is sooner;

Amended Eff. January 1, 2015; December 1, 2005; June 1, 2004; July 1, 1998; July 1, 1996; July 1, 1994;

Readopted Eff. January 1, 2018.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑213;

Eff. February 1, 1976;

Amended Eff. December 1, 1976;

Repealed Eff. July 1, 1984.

15A NCAC 02D .0103 COPIES OF REFERENCED FEDERAL REGULATIONS

Copies of the Code of Federal Regulations sections referred to in this Subchapter may be obtained free of charge online at https://www.govinfo.gov/app/collection/cfr/. Copies of referenced rules are also available for public inspection at Department of Environmental Quality regional offices upon request. The contact information for the regional offices is provided on the Division of Air Quality website at https://deq.nc.gov/about/divisions/air-quality/regional-offices.

History Note: Authority G.S. 143‑215.3; 150B‑21.6;

Eff. December 1, 1976;

Amended Eff. December 1, 2005; December 1, 1992; August 1, 1991; July 1, 1988; July 1, 1987;

Pursuant to G.S. 150B-21.3A, rule is necessary without substantive public interest Eff. January 5, 2016;

Amended Eff. September 1, 2023; January 1, 2018.

15A NCAC 02D .0104 INCORPORATION BY REFERENCE

(a) If referred to in this Subchapter, the following materials shall be incorporated in this Subchapter by reference:

(1) a regulation codified in the Code of Federal Regulations (CFR); and

(2) a method established by the American Society for Testing and Materials (ASTM).

(b) The Code of Federal Regulations and American Society for Testing and Materials methods incorporated by reference in this Subchapter shall include subsequent amendments and editions unless a rule specifies otherwise.

(c) The Code of Federal Regulations is available in electronic form free of charge at https://www.gpo.gov/fdsys/search/home.action.

(d) The American Society for Testing and Materials methods may be purchased from https://www.astm.org/. Purchase price varies according to the particular test method and format chosen, and the cost of the materials are set forth at https://www.astm.org/.

History Note: Authority G.S. 150B‑21.6;

Eff. July 1, 1988;

Amended Eff. July 1, 1998; May 1, 1995; December 1, 1992; October 1, 1989;

Pursuant to G.S. 150B-21.3A, rule is necessary without substantive public interest Eff. January 5, 2016;

Amended Eff. January 1, 2018.

15A NCAC 02D .0105 MAILING LIST

(a) The Division shall develop and maintain a mailing list of persons who have requested notification of rule-making as required by G.S. 150B 21.2(d). Such persons shall receive a copy of the complete notice as filed with the Office of Administrative Hearings.

(b) Any person requesting to be on a mailing list established under Paragraph (a) of this Rule shall submit a written request to the Division of Air Quality, 1641 Mail Service Center, Raleigh, North Carolina, 27699-1641. Payment of fees required under this Rule may be by check or money order for thirty dollars ($30.00) made payable to the Department of Environmental Quality. Payment shall be submitted with each request and received by June 1 of each year. The fee covers from July 1 to June 30 of the following year. A person requesting to be on the list for notification of rule-making may opt to receive notification via email free of charge by contacting Division staff as shown at https://deq.nc.gov/about/divisions/air-quality/air-quality-planning.

History Note: Authority G.S. 143-215.3(a)(1); 150B 21.2(d);

Eff. April 1, 1995;

Amended Eff. April 1, 2003; July 1, 1998; May 1, 1998;

Pursuant to G.S. 150B-21.3A, rule is necessary without substantive public interest Eff. January 5, 2016;

Amended Eff. January 1, 2018.

SECTION .0200 ‑ AIR POLLUTION SOURCES

15A NCAC 02D .0201 CLASSIFICATION OF AIR POLLUTION SOURCES

(a) Purpose. This Rule establishes a system for classifying air pollution sources. The Commission shall use the system for classifying air pollution sources set forth in this Rule to classify air pollution sources governed by this Subchapter.

(b) Scope. This Rule shall apply to all air pollution sources, both combustion and non‑combustion. The following system for classifying air pollution sources shall be used:

(1) "Class I‑C" includes all sources of air pollution using fuel-burning equipment for the production of heat to generate electricity for public use.

(2) "Class II‑C" includes all sources of air pollution using fuel-burning equipment for the production of steam, and for other process uses at commercial and industrial establishments.

(3) "Class III‑C" includes all sources of air pollution using fuel-burning equipment for comfort heating at institutional, commercial, or industrial establishments, or at apartment houses having a central heating system serving more than four apartments.

(4) "Class IV‑C" includes all sources of air pollution that burn trash, rubbish, refuse, or similar materials in incinerators, teepee burners, or similar devices.

(5) "Class V‑C" includes all sources of air pollution using fuel-burning equipment for comfort heating that are not included in Class III‑C.

(6) "Class VI‑C" includes all sources of air pollution using internal combustion engines.

(7) "Class I‑I" includes all sources of air pollution resulting from industrial plants engaged in the manufacture of chemicals or allied products whose processes depend on the chemical reaction of two or more elements or compounds, and includes plants producing acids, fertilizer materials, dyestuff, synthetic fibers, and industrial gases.

(8) "Class II‑I" includes all sources of air pollution resulting from industrial plants engaged in the production of pulp and paper.

(9) "Class III‑I" includes all sources of air pollution resulting from the mining and processing of minerals, stone, clay, and cement products, and includes phosphate ore, mica and feldspar operations, stone quarries and crushers, cement plants, concrete mixing plants, and masonry block plants.

(10) "Class IV‑I" includes all sources of air pollution resulting from industrial operations using petroleum products, and includes asphalt mix plants, roofing felt plants, and petroleum products storage areas.

(11) "Class V‑I" includes all sources of air pollution resulting from furniture, lumber, or wood product plants.

(12) "Class VI‑I" includes all sources of air pollution resulting from textile manufacturing, textile dyeing, or finishing plants.

(13) "Class VII‑I" includes all sources of air pollution resulting from the shelling, drying, storage, ginning, and processing of tobacco, corn, soybeans, peanuts, cotton, fruits, vegetables, or other agricultural products.

(14) "Class VIII‑I" includes all sources of air pollution resulting from industries engaged in the processing of metals, and includes smelting, casting foundries, metal working, and other similar operations.

(15) "Class IX‑I" includes all sources of air pollution resulting from slaughtering and processing of meat, poultry, fish, and similar products and from rendering or the recovering of by‑products of these operations.

(16) "Class X‑I" includes all sources of air pollution resulting from industries which do not fall within the classifications described in Subparagraphs (b)(7) through (b)(15) of this Rule.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(4);

Eff. February 1, 1976;

Amended Eff. July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0202 REGISTRATION OF AIR POLLUTION SOURCES

(a) The Director may require the owner or operator of a source of air pollution to register that source, pursuant to G.S. 143 215.107(a)(4).

(b) Any person required to register a source of air pollution with the Division shall register the source on forms provided by the Division and shall provide the following information:

(1) the name of the person, company, or corporation operating the sources;

(2) the address, location, and county;

(3) principal officer of the company;

(4) quantities and kinds of raw materials used;

(5) process flow sheets;

(6) operating schedules;

(7) total weights and kinds of air pollution released;

(8) types and quantities of fuels used;

(9) stack heights; and

(10) other information considered essential in evaluating the potential of the source to cause air pollution.

The forms shall be completed and returned to the Division within 60 days following their receipt.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(4);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; June 1, 1985; July 1, 1984;

Readopted Eff. January 1, 2018.

SECTION .0300 ‑ AIR POLLUTION EMERGENCIES

15A NCAC 02D .0301 PURPOSE

Notwithstanding any other provisions of air pollution control regulations or standards, this Section is designed to prevent the excessive buildup of air contaminants during air pollution episodes thereby preventing the occurrence of an emergency due to the effects of these contaminants on the public health.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.3(a)(12);

Eff. February 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0302 EPISODE CRITERIA

The Director may issue a proclamation of an air pollution alert, air pollution warning, or air pollution emergency if the Director determines that the accumulation of air contaminants in any place is attaining or has attained levels that could, if such levels are sustained or exceeded, lead to a threat to the health of the public. In deciding whether to issue such a proclamation, the Director shall be guided by the following criteria:

(1) Alert. The alert level is that concentration of pollutants at which first stage control actions are to begin. The Secretary of the Department of Environmental Quality with the concurrence of the Governor shall proclaim an alert when any of the following levels is reached at any monitoring site and meteorological conditions are such that pollutant concentrations can be expected to remain at or exceed above levels for 12 or more hours or, in the case of ozone, the situation is likely to reoccur within the next 24-hours unless control actions are taken:

(a) sulfur dioxide -- 800 µg/m3 (0.3 ppm), 24-hour average;

(b) carbon monoxide -- 17 µg/m3 (15 ppm), eight-hour average;

(c) ozone -- 400 µg/m3 (0.2 ppm), one-hour average;

(d) nitrogen dioxide -- 1130 µg/m3 (0.6 ppm), one-hour average; 282 µg/m3 (0.15 ppm), 24-hour average; or

(e) PM10--350 µg/m3 24-hour average.

(2) Warning. The warning level indicates that air quality is continuing to degrade and that additional abatement actions are necessary. The Secretary of the Department of Environmental Quality with the concurrence of the Governor shall proclaim a warning when any one of the following levels is reached at any monitoring site and meteorological conditions are such that pollutant concentrations can be expected to remain at or exceed above levels for 12 or more hours or, in the case of ozone, the situation is likely to reoccur within the next 24-hours unless control actions are taken:

(a) sulfur dioxide -- 1600 µg/m3 (0.6 ppm),24-hour average

(b) carbon monoxide -- 34 µg/m3 (30 ppm), eight-hour average;

(c) ozone -- 800 µg/m3 (0.4 ppm), one-hour average;

(d) nitrogen dioxide -- 2260 µg/m3 (1.2 ppm), one-hour average; 565 µg/m3 (0.3 ppm), 24-hour average; or

(e) PM10 -- 420 µg/m3 24-hour average.

(3) Emergency. The emergency level indicates that air quality is continuing to degrade to a level that the most stringent control actions are necessary. The Secretary of the Department of Environmental Quality with the concurrence of the Governor shall declare an emergency when any one of the following levels is reached at any monitoring site and meteorological conditions are such that pollutant concentrations can be expected to remain at or exceed above levels for 12 or more hours or, in the case of ozone, the situation is likely to reoccur within the next 24-hours unless control actions are taken:

(a) sulfur dioxide -- 2100 µg/m3 (0.8 ppm) 24-hour average;

(b) carbon monoxide -- 46 µg/m3 (40 ppm), eight-hour average;

(c) ozone -- 1000 µg/m3 (0.5 ppm), one-hour average;

(d) nitrogen dioxide -- 3000 µg/m3 (1.6 ppm), one-hour average; 750 µg/m3 (0.4 p.p.m.), 24-hour average; or

(e) PM10--500 µg/m3 24-hour average.

(4) Termination. After a proclamation has been issued, any level reached by application of these criteria shall remain in effect until the criteria for that level are no longer met. At that time the next lower level shall remain in effect until the criteria for that level are no longer met.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.3(a)(12);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; July 1, 1988; July 1, 1984; June 1, 1980; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0303 EMISSION REDUCTION PLANS

(a) Air Pollution Alert. Any person responsible for the operation of a source of air pollution described in 15A NCAC 02D .0305 shall take all air pollution alert actions required for that source and shall put into effect the preplanned abatement program that is required by 15A NCAC 02D .0304 for an air pollution alert.

(b) Air Pollution Warning. Any person responsible for the operation of a source of air pollution described in 15A NCAC 02D .0306 shall take all air pollution warning actions required for that source and shall put into effect the preplanned abatement program that is required by 15A NCAC 02D .0304 for an air pollution warning.

(c) Air Pollution Emergency. Any person responsible for the operation of a source of air pollution described in 15A NCAC 02D .0307 shall take all air pollution emergency actions required for that source and shall put into effect the preplanned abatement program that is required by 15A NCAC 02D .0304 for an air pollution emergency.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.3(a)(12);

Eff. February 1, 1976;

Amended Eff. July 1, 1984;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0304 PREPLANNED ABATEMENT PROGRAM

(a) Any person who is responsible for the operation of a source of air pollution that is described in 15A NCAC 02D .0305, .0306, or .0307 or that emits 100 tons per year or more of any one pollutant shall prepare an abatement program plan to reduce the emissions of air pollutants into the outdoor atmosphere during periods of an air pollution episode as described in 15A NCAC 02D .0302. The plan shall be consistent with good industrial practices and safe operating procedures. When the Director requests that the plan be submitted for review, the owner or operator of the source shall submit the plan within 30 days of the Director's request.

(b) When requested by the Commission in writing, any person responsible for the operation of a source not described in 15A NCAC 02D .0305, .0306, or .0307 shall prepare a plan to reduce the emissions of air pollutants into the outdoor atmosphere during periods of air pollution alert, air pollution warning, and air pollution emergency as described in 15A NCAC 02D .0302. The plan shall be consistent with good industrial practices and safe operating procedures.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.3(a)(12);

Eff. February 1, 1976;

Amended Eff. July 1, 1988; July 1, 1984;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0305 EMISSION REDUCTION PLAN: ALERT LEVEL

(a) General.

(1) There shall be no open burning of any material otherwise allowed under 15A NCAC 02D .1900.

(2) The use of incinerators for the disposal of any form of solid waste shall be limited to the hours between noon and 4:00 p.m.

(3) Persons operating fuel burning equipment which requires boiler lancing or soot blowing shall perform such operations only between the hours of noon and 4:00 p.m.

(4) Persons operating motor vehicles should eliminate all unnecessary operations.

(b) Source Curtailment. Any person responsible for the operation of a source of air pollution shall take all required control actions for the alert level that are listed below:

(1) Operators of coal or oil fired electric power generating facilities shall:

(A) use fuels having low ash and sulfur content,

(B) perform boiler lancing and soot blowing between noon and 4:00 p.m., and

(C) divert electric power generation to facilities outside of the alert area;

(2) Operators of coal or oil fired process steam generating facilities shall:

(A) use fuels having low ash and sulfur content,

(B) perform boiler lancing and soot blowing between noon and 4:00 p.m., and

(C) reduce steam load demands consistent with continuing plant operation;

(3) Operators of manufacturing industries of the following classifications: primary metals industry; petroleum refining and related industries; chemical and allied products industries; paper and allied products industries; glass, clay, and concrete products industries shall:

(A) reduce air pollutants from manufacturing operations by curtailing, postponing, or deferring production and related operations;

(B) defer trade waste disposal operations that emit particles, gases, vapors, or malodorous substances;

(C) reduce heat-load demands for processing; and

(D) perform boiler lancing or soot blowing between noon to 4:00 p.m.; and

(4) Other persons requested by the Commission to prepare a preplanned abatement program shall take all required control actions for the alert level contained in their program plan.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.3(a)(12);

Eff. February 1, 1976;

Amended Eff. July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0306 EMISSION REDUCTION PLAN: WARNING LEVEL

(a) General

(1) There shall be no open burning of any material otherwise allowed under 15A NCAC 02D .1900.

(2) The use of incinerators for the disposal of solid waste or liquid waste shall be prohibited.

(3) Persons operating fuel-burning equipment which requires boiler lancing or soot blowing shall perform such operations only between noon and 4:00 p.m..

(4) Persons operating motor vehicles should minimize their use through car pools and increased use of public transportation.

(b) Source Curtailment. Any person responsible for the operation of a source of air pollution shall take all required control actions for the warning level that are listed below:

(1) Operators of coal or oil fired electric power generating facilities shall:

(A) use fuels having the lowest ash and sulfur content;

(B) perform boiler lancing and soot blowing between noon to 4:00 p.m.; and

(C) divert electric power generating to facilities outside of the warning area;

(2) Operators of coal or oil fired process steam generating facilities shall:

(A) use fuels having the lowest ash and sulfur content;

(B) perform boiler lancing and soot blowing between noon to 4:00 p.m.;

(C) reduce steam load demands consistent with continuing plant operations; and

(D) prepare to use the preplanned abatement program for emergency level;

(3) Operators of manufacturing industries of the following classifications: primary metal industries; petroleum refining and related industries; chemical and allied products industries; paper and allied products industries; glass, clay, and concrete products industries shall:

(A) reduce air pollutants from manufacturing operations by, if necessary, assuming reasonable economic hardship by postponing production and related operations;

(B) defer trade waste disposal operations that emit particles, gases, vapors, or malodorous substances;

(C) reduce heat-load demands for processing consistent with continuing plant operations; and

(D) perform boiler lancing or soot blowing between noon to 4:00 p.m.; and

(4) Other persons requested by the Commission to prepare a preplanned abatement program shall take all required control actions for the warning level contained in their program plan.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.3(a)(12);

Eff. February 1, 1976;

Amended Eff. July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0307 EMISSION REDUCTION PLAN: EMERGENCY LEVEL

(a) General

(1) There shall be no open burning of any material otherwise allowed under 15A NCAC 02D .1900.

(2) The use of incinerators for the disposal of any form of solid or liquid waste shall be prohibited.

(3) All places of employment described below shall cease operations:

(A) mining and quarrying of nonmetallic minerals;

(B) all manufacturing establishments except those required to have in force a preplanned abatement program for an air pollution emergency;

(C) all construction work involving grading or other operations that generate dust;

(D) all wholesale and retail establishments except pharmacies and stores primarily engaged in the sale of food;

(E) all commercial and manufacturing establishments, automobile repair services and garages, laundries, barbershops, beauty shops, and motion picture theaters; and

(F) elementary and secondary schools, colleges, universities, and professional schools.

(4) The use of motor vehicles is prohibited except in emergencies with the approval of local or state police.

(b) Source Curtailment. Any person responsible for the operation of a source of air pollution shall take all required control actions for the emergency level that are listed below:

(1) Operators of coal- or oil-fired electric power generating facilities shall:

(A) use fuels having lowest ash and sulfur content;

(B) perform boiler lancing or soot blowing between noon to 4:00 p.m.;

(C) divert electric power generation to facilities outside of emergency area;

(2) Operators of coal- or oil-fired process steam generating facilities shall:

(A) reduce heat and steam demands to that necessary to prevent equipment damage;

(B) perform boiler lancing and soot blowing between noon and 4:00 p.m.;

(C) take the action called for in the preplanned abatement program;

(3) Operators of manufacturing industries of the following classifications: primary metals industries; petroleum refining and related industries; chemical and allied products industries; paper and allied products industries; glass, clay, and concrete products industries shall:

(A) eliminate air pollutants from manufacturing operations by ceasing, curtailing, postponing, or deferring production and related operations to the extent possible without causing injury to persons or damage to equipment;

(B) eliminate air pollution from trade waste disposal processes which emit particles, gases, vapors, or malodorous substances;

(C) reduce heat-load demands for processing to the minimum;

(D) perform boiler lancing or soot blowing between 12:00 p.m. to 4:00 p.m.; and

(4) Other persons requested by the Commission to prepare a preplanned abatement program shall take all required control actions for the emergency level contained in their program plan.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.3(a)(12);

Eff. February 1, 1976;

Amended Eff. July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

SECTION .0400 ‑ AMBIENT AIR QUALITY STANDARDS

15A NCAC 02D .0401 PURPOSE

(a) The purpose of the ambient air quality standards set out in this Section is to establish certain maximum limits on parameters of air quality considered desirable for the preservation and enhancement of the quality of the State's air resources. Furthermore, the objective of the Commission, consistent with the North Carolina Air Pollution Control Law, shall be to prevent significant deterioration in ambient air quality in any substantial portion of the State where existing air quality is better than the standards. An atmosphere in which these standards are not exceeded should provide for the protection of the public health, plant and animal life, and property.

(b) Ground-level concentrations of pollutants shall be determined by sampling at fixed locations in areas beyond the premises on which a source is located. The standards shall be applicable at each such sampling location in the State.

(c) No facility or source of air pollution shall cause any ambient air quality standard in this Section to be exceeded or contribute to a violation of any ambient air quality standard in this Section except as allowed by 15A NCAC 02D .0531 or .0532.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. December 1, 1992; October 1, 1989; July 1, 1984;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0402 SULFUR OXIDES

(a) The ambient air quality standards for sulfur oxides measured as sulfur dioxide shall be:

(1) 80 micrograms per cubic meter (0.03 ppm) annual arithmetic mean;

(2) 365 micrograms per cubic meter (0.14 ppm) maximum 24-hour concentration not to be exceeded more than once per year; and

(3) 1300 micrograms per cubic meter (0.5 ppm) maximum three-hour concentration not to be exceeded more than once per year.

(b) Sampling and analysis shall be in accordance with procedures in Appendix A or A-1 of 40 CFR Part 50 or by a Federal Equivalent Method (FEM) designated in accordance with 40 CFR Part 53.

(c) Applicability of the standards listed in Subparagraph (a)(1) and (2) of this Rule shall be in effect until one year after the effective date of initial designations under Section 107(d) of the Clean Air Act for the sulfur dioxide standard in Paragraph (d) of this Rule.

(d) The primary one-hour annual ambient air quality standard for oxides of sulfur shall be 75 parts per billion (ppb), measured in the ambient air as sulfur dioxide.

(e) The one-hour primary standard shall be met at an ambient air quality monitoring site when the three-year average of the annual (99th percentile) of the daily maximum one-hour average concentrations is less than or equal to 75 ppb, as determined in accordance with Appendix T of 40 CFR Part 50.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. September 1, 2011; July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0403 TOTAL SUSPENDED PARTICULATES

(a) The ambient air quality standards for total suspended particulate matter are:

(1) 75 micrograms per cubic meter annual geometric mean; and

(2) 150 micrograms per cubic meter maximum 24‑hour concentration not to be exceeded more than once per year.

(b) Sampling and analysis shall be in accordance with procedures in 40 CFR Part 50, Appendix B or equivalent methods established pursuant to 40 CFR Part 53.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. July 1, 1988; July 1, 1984; October 15, 1981;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0404 CARBON MONOXIDE

(a) The ambient air quality standards for carbon monoxide shall be:

(1) 9 parts per million (10 milligrams per cubic meter) maximum eight‑hour average concentration not to be exceeded more than once per year; and

(2) 35 parts per million (40 milligrams per cubic meter) maximum one‑hour average concentration not to be exceeded more than once per year.

(b) Sampling and analysis shall be in accordance with procedures in Appendix C of 40 CFR Part 50 or equivalent methods established under 40 CFR Part 53.

(c) An eight‑hour average shall be considered valid if at least 75 percent of the hourly averages for the eight‑hour period are available. In the event that only six or seven hourly averages are available, the eight‑hour average shall be computed on the basis of the hours available using six or seven as the divisor.

(d) When summarizing data for comparison with the standards, averages shall be stated to one decimal place. Comparison of the data to the standards in parts per million shall be made in terms of integers with fractional parts of 0.5 or greater rounded up.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. October 1, 1989; July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0405 OZONE

The ambient air quality standard for ozone measured by a reference method based on Appendix D of 40 CFR Part 50 and designated according to 40 CFR Part 53 shall be 0.070 parts per million (ppm), daily maximum eight-hour average. The standard shall be deemed attained at an ambient air quality monitoring site when the average of the annual fourth-highest daily maximum eight-hour average ozone concentration is less than or equal to 0.070 parts per million (ppm) as determined by Appendix U of 40 CFR Part 50, or equivalent methods established under 40 CFR Part 53.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. January 1, 2010; April 1, 1999; July 1, 1984; July 1, 1979; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0406 HYDROCARBONS

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. December 1, 1976;

Repealed Eff. July 1, 1984.

15A NCAC 02D .0407 NITROGEN DIOXIDE

(a) The primary annual ambient air quality standard for oxides of nitrogen shall be 53 parts per billion annual average concentration measured in the ambient air as nitrogen dioxide.

(b) The primary one-hour ambient air quality standard for oxides of nitrogen shall be 100 parts per billion one hour annual average concentration measured in the ambient air as nitrogen dioxide.

(c) The secondary ambient air quality standard for nitrogen dioxide shall be 0.053 parts per million (100 micrograms per cubic meter) annual arithmetic mean concentration.

(d) Sampling and analysis shall be in accordance with:

(1) procedures in Appendix F of 40 CFR Part 50; or

(2) by a Federal Equivalent Method (FEM) designated in accordance with 40 CFR Part 53.

(e) The annual primary standard shall be deemed attained when the annual average concentration in a calendar year is less than or equal to 53 parts per billion, as determined in accordance with Appendix S of 40 CFR Part 50 for the annual standard.

(f) The one hour primary standard shall be deemed attained when the three-year average of the annual 98th percentile of the daily maximum one-hour average concentration is less than or equal to 100 ppb, as determined in accordance with Appendix S of 40 CFR Part 50 for one-hour standard.

(g) The secondary standard shall be deemed attained when the annual arithmetic mean concentration in a calendar year is less than or equal to 0.053 parts per million, rounded to three decimal places (fractional parts equal to or greater than 0.0005 parts per million are rounded up). To demonstrate attainment, an annual mean shall be based on hourly data that are at least 75 percent complete or on data derived from manual methods that are at least 75 percent complete for the scheduled sampling days in each calendar quarter.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(3);

Eff. February 1, 1976;

Amended Eff. September 1, 2011; October 1, 1989; July 1, 1984; December 1, 1976;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0408 LEAD

The ambient air quality standard for lead and its compounds, measured as elemental lead by a reference method based on Appendix G of 40 CFR Part 50 or by an equivalent method established under 40 CFR Part 53, shall be 0.15 micrograms per cubic meter. The standard shall be deemed met when the maximum arithmetic three-month mean concentration for a three-year period, as determined in accordance with Appendix R of 40 CFR Part 50, is less than or equal to 0.15 micrograms per cubic meter.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(3);

Eff. June 1, 1980;

Amended Eff. January 1, 2010; July 1, 1984;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0409 PM10 PARTICULATE MATTER

(a) The ambient air quality standard for PM10 particulate matter shall be 150 micrograms per cubic meter (µg/m3), 24-hour average concentration. This standard shall be deemed attained when 150 (µg/m3), as determined according to Appendix N of 40 CFR Part 50, is not exceeded more than once per year on average over a three-year period.

(b) For the purpose of determining attainment of the standards in Paragraph (a) of this Rule, particulate matter shall be measured in the ambient air as PM10 (particles with an aerodynamic diameter less than or equal to a nominal 10 micrometers) by either:

(1) a reference method based on Appendix M of 40 CFR Part 50 and designated according to 40 CFR Part 53; or

(2) an equivalent method designated according to 40 CFR Part 53.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(3);

Eff. July 1, 1988;

Amended Eff. January 1, 2010; April 1, 1999;

Readopted Eff. January 1, 2018.

15A NCAC 02D .0410 PM2.5 PARTICULATE MATTER

(a) The primary ambient air quality standards for PM2.5 shall be 9.0 micrograms per cubic meter (µg/m3) annual arithmetic mean concentration and 35 µg/m3 24-hour average concentration measured in the ambient air as PM2.5 (particles with an aerodynamic diameter less than or equal to a nominal 2.5 micrometers) by either:

(1) A reference method based on appendix L to 40 CFR Part 50 and designated in accordance with 40 CFR Part 53; or

(2) An equivalent method designated in accordance with 40 CFR Part 53.

(b) The primary annual PM2.5 standard shall be deemed met when the annual arithmetic mean concentration, as determined in accordance with Appendix N of 40 CFR Part 50, is less than or equal to 9.0 µg/m3.

(c) The primary 24-hour PM2.5 standard shall be deemed met when the 98th percentile 24-hour concentration, as determined in accordance with Appendix N of 40 CFR Part 50, is less than or equal to 35 µg/m3.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(3);

Eff. April 1, 1999;

Amended Eff. September 1, 2015; January 1, 2010;

Readopted Eff. January 1, 2018;

Amended Eff. March 1, 2025.

SECTION .0500 ‑ EMISSION CONTROL STANDARDS

15A NCAC 02D .0501 COMPLIANCE WITH EMISSION CONTROL STANDARDS

(a) Purpose and Scope. The purpose of this Rule is to assure compliance with emission control standards found in this Section. This Rule shall apply to all air pollution sources, both combustion and non‑combustion.

(b) New sources shall be in compliance prior to beginning operations.

(c) The owner or operator of an air pollution source shall operate or control the source in a manner to meet emission standards in this Section and not cause the ambient air quality standards pursuant to 15A NCAC 02D .0400 to be exceeded at any point beyond the premises on which the source is located. When controls more stringent than those named in the applicable emission standards in this Section are required to prevent violation of the ambient air quality standards or are required to create an offset, the permit shall contain a condition requiring these controls.

(d) The Bubble Concept. As provided in this Paragraph, a facility with multiple emission sources or multiple facilities within the same area may choose to meet the total emission limitation for a given pollutant through a different mix of controls than those required by the rules in 15A NCAC 02D .0500 or .0900.

(1) In order for this mix of alternative controls to be permitted, the Director shall determine that the following conditions are met:

(A) Sources pursuant to which 15A NCAC 02D .0524, .0530, .0531, .1110, or .1111, the federal New Source Performance Standards (NSPS), the federal National Emission Standards for Hazardous Air Pollutants (NESHAP), regulations established pursuant to Section 111(d) of the federal Clean Air Act, or state or federal Prevention of Significant Deterioration (PSD) requirements apply shall have emissions no larger than if there were not an alternative mix of controls;

(B) The facility or facilities is located in an attainment area, an unclassifiable area, or in an area that has been demonstrated to be attainment by the statutory deadlines with reasonable further progress toward attainment for those pollutants being considered;

(C) All of the emission sources affected by the alternative mix are in compliance with applicable regulations or are in compliance with established compliance agreements; and

(D) The review of an application for the proposed mix of alternative controls and the enforcement of the resulting permit shall not require expenditures of State funds in excess of five times that which would otherwise be required for the review and enforcement of permits without an alternative mix of controls.

(2) The owners or operators of the facility or facilities shall demonstrate the alternative mix of controls is equivalent in total allowed emissions, reliability, enforceability, and environmental impact to the aggregate of the individual emission standards to which the facility would be subject without the alternative mix of controls; and

(A) that the alternative mix approach does not interfere with the attainment and maintenance of the ambient air quality standards and does not interfere with the Prevention of Significant Deterioration (PSD) program, which shall include modeled calculations of the amount, if any, of PSD increment consumed or created as defined in Clean Air Act Section 163;

(B) that the alternative mix approach conforms with reasonable further progress requirements as defined in Clean Air Act Section 171(1) if the source is located in a nonattainment area;

(C) that the emissions pursuant to the alternative mix approach are quantifiable, and emission trades among the sources involved in the alternative mix approach are equivalent; and

(D) that the pollutants controlled pursuant to the alternative mix approach are of the same criteria pollutant categories, except that emissions of criteria pollutants that contain hazardous pollutants and are used in alternative emission control strategies are subject to the limitations as defined in 44 Fed. Reg. 71784 (December 11, 1979), Subdivision D.1.c.ii. The Federal Register referenced in this Part is incorporated by reference and does not include subsequent amendments or editions. A copy of 44 Fed. Reg. 71784 may be obtained free of charge and found online at https://www.govinfo.gov/content/pkg/FR-1979-12-11/pdf/FR-1979-12-11.pdf.

The demonstrations of equivalence shall be performed with at least the same level of detail as State Implementation Plan (SIP) demonstration of attainment for the area. A copy of the SIPs may be found on the Division of Air Quality (DAQ) website at https://deq.nc.gov/about/divisions/air-quality/air-quality-planning/state-implementation-plans. If the facility involves another facility in the alternative strategy, it shall complete a modeling demonstration to ensure that air quality is protected. Demonstrations of equivalency shall take into account differences in the level of reliability of the control measures or other uncertainties.

(3) The emission rate limitations or control techniques of each source within the facility or facilities subjected to the alternative mix of controls shall be specified in the facility's permit or facilities' permits.

(4) Compliance schedules and enforcement actions shall not be affected because an application for an alternative mix of controls is being prepared or is being reviewed.

(5) The Director may waive or reduce requirements in this Paragraph up to the extent allowed by the Emissions Trading Policy Statement published in the Federal Register of April 7, 1982, pages 15076‑15086, provided that the analysis required by Paragraph (e) of this Rule supports the waiver or reduction of requirements. The Federal Register referenced in this Subparagraph is incorporated by reference and does not include subsequent amendments or editions.

(e) In a permit application for an alternative mix of controls pursuant to Paragraph (d) of this Rule, the owner or operator of the facility shall demonstrate the proposal is equivalent to the existing requirements of the SIP in total allowed emissions, enforceability, reliability, and environmental impact. The Director shall provide for public notice with an opportunity to request a public hearing following the procedures pursuant to 15A NCAC 02Q .0300 or .0500, as applicable.

(1) If a permit containing these conditions is issued pursuant to 15A NCAC 02Q .0300, it shall become a part of the state implementation plan (SIP) as an appendix available for inspection as specified in 15A NCAC 02Q .0105. Until the U.S. Environmental Protection Agency (EPA) approves the SIP revision embodying the permit containing an alternative mix of controls, the facility shall continue to meet the otherwise applicable existing SIP requirements.

(2) If a permit containing these conditions is issued pursuant to 15A NCAC 02Q .0500 it shall be available for inspection as specified in 15A NCAC 02Q .0105. Until the EPA approves the Title V permit containing an alternative mix of controls, the facility shall continue to meet the otherwise applicable existing SIP requirements.

The revision shall be submitted for approval by the EPA on the basis of the revision's consistency with EPA's "Policy for Alternative Emission Reduction Options Within State Implementation Plans" as promulgated in the Federal Register of December 11, 1979, pages 71780‑71788, and subsequent rulings.

(f) If the owner or operator of a combustion or noncombustion source or control equipment subject to the requirements of this Section is required to demonstrate compliance with a rule in this Section, source testing procedures pursuant to 15A NCAC 02D .2600 shall be used.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. August 1, 1991; October 1, 1989;

Temporary Amendment Eff. March 8, 1994 for a period of 180 days or until the permanent rule is effective, whichever is sooner;

Amended Eff. June 1, 2008; April 1, 2001; April 1, 1999; July 1, 1996; February 1, 1995; July 1, 1994;

Readopted Eff. November 1, 2020;

Amended Eff. September 1, 2023.

15A NCAC 02D .0502 PURPOSE

The purpose of the emission control standards set out in this Section is to establish maximum limits on the rate of emission of air contaminants into the atmosphere.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. June 1, 1981;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0503 PARTICULATES FROM FUEL BURNING INDIRECT HEAT EXCHANGERS

(a) For the purpose of this Rule, the following definitions shall apply:

(1) "Functionally dependent" means that structures, buildings, or equipment are interconnected through common process streams, supply lines, flues, or stacks.

(2) "Indirect heat exchanger" means any equipment used for the alteration of the temperature of one fluid by the use of another fluid in which the two fluids are separated by an impervious surface such that there is no mixing of the two fluids.

(3) "Plant site" means any single or collection of structures, buildings, facilities, equipment, installations, or operations that:

(A) are located on one or more adjacent properties;

(B) are under common legal control; and

(C) are functionally dependent in their operations.

(b) The definition contained in Subparagraph (a)(3) of this Rule does not affect the calculation of the allowable emission rate of any indirect heat exchanger permitted prior to April 1, 1999.

(c) The emissions of particulate matter from the combustion of a fuel that are discharged from any indirect heat exchanger through a stack or chimney into the atmosphere shall not exceed:

Allowable Emission Limit

Maximum Heat Input In For Particulate Matter In

Million Btu/Hour lb/Million Btu

Up to and Including 10 0.60

100 0.33

1,000 0.18

10,000 and Greater 0.10

For a heat input between any two consecutive heat inputs stated in the table set forth in this Paragraph, the allowable emissions of particulate matter shall be calculated by the equation E= 1.090*Q-0.2594. "E" equals the allowable emission limit for particulate matter in lb/million Btu. "Q" equals the maximum heat input in million Btu/hour.

(d) This Rule applies to installations in which fuel is burned for the purpose of producing heat or power by indirect heat transfer. For the purpose of this Rule, the term "fuels" includes all fuels that generate particulate matter emissions from indirect heat exchangers excluding wood and refuse not burned as a fuel. When any refuse, products, or by‑products of a manufacturing process are burned as a fuel rather than refuse, or in conjunction with any fuel, this allowable emission limit shall apply.

(e) For the purpose of this Rule, the maximum heat input shall be the total heat content of all fuels which are burned in a fuel burning indirect heat exchanger, of which the combustion products are emitted through a stack or stacks. The sum of maximum heat input of all fuel burning indirect heat exchangers at a plant site which are in operation, under construction, or permitted pursuant to 15A NCAC 02Q, shall be considered as the total heat input for the purpose of determining the allowable emission limit for particulate matter for each fuel burning indirect heat exchanger. Fuel burning indirect heat exchangers constructed or permitted after February 1, 1983, shall not change the allowable emission limit of any other fuel burning indirect heat exchanger whose allowable emission limit has previously been set. The removal of a fuel burning indirect heat exchanger shall not change the allowable emission limit of any other fuel burning indirect heat exchanger whose allowable emission limit has previously been established. However, for any fuel burning indirect heat exchanger constructed after, or in conjunction with, the removal of another fuel burning indirect heat exchanger at the plant site, the maximum heat input of the removed fuel burning indirect heat exchanger shall no longer be considered in the determination of the allowable emission limit of any fuel burning indirect heat exchanger constructed after or in conjunction with the removal. For the purposes of this Paragraph, refuse not burned as a fuel and wood shall not be considered a fuel. For residential facilities or institutions, such as military and educational, whose primary fuel burning capacity is for comfort heat, only those fuel burning indirect heat exchangers located in the same power plant or building or otherwise physically interconnected, such as common flues, steam, or power distribution line, shall be used to determine the total heat input.

(f) The emission limit for fuel burning equipment that burns both wood and other fuels in combination, or for wood and other fuel burning equipment that is operated such that emissions are measured on a combined basis, shall be calculated by the equation Ec = [(EW)(Qw) + (Eo)(Qo)] /Qt.

(1) Ec = the emission limit for combination or combined emission source(s) in lb/million Btu.

(2) Ew = plant site emission limit for wood only as determined pursuant to 15A NCAC 02D .0504 in lb/million Btu.

(3) Eo = the plant site emission limit for other fuels only as determined by Paragraphs (a), (b) and (c) of this Rule in lb/million Btu.

(4) Qw = the actual wood heat input to the combination or combined emission source(s) in Btu/hr.

(5) Qo = the actual other fuels heat input to the combination or combined emission source(s) in Btu/hr.

(6) Qt = Qw + Qo and is the actual total heat input to combination or combined emission source(s) in Btu/hr.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Temporary Amendment Eff. March 8, 1994 for a period of 180 days or until the permanent rule is effective, whichever is sooner;

Amended Eff. April 1, 1999; July 1, 1994; August 1, 1991; June 1, 1985; February 1, 1983;

Readopted Eff. November 1, 2020;

Amended Eff. November 1, 2023.

15A NCAC 02D .0504 PARTICULATES FROM WOOD BURNING INDIRECT HEAT EXCHANGERS

(a) This Rule applies to fuel burning equipment that burns 100 percent wood. All other fuel burning equipment that burns both wood and other fuels in combination shall be subject to 15A NCAC 02D .0503. For the purpose of this Rule, the following definitions shall apply:

(1) "Functionally dependent" means that structures, buildings or equipment are interconnected through common process streams, supply lines, flues, or stacks.

(2) "Indirect heat exchanger" means any equipment used for the alteration of the temperature of one fluid by the use of another fluid in which the two fluids are separated by an impervious surface such that there is no mixing of the two fluids.

(3) "Plant site" means any single or collection of structures, buildings, facilities, equipment, installations, or operations that:

(A) are located on one or more adjacent properties;

(B) are under common legal control; and

(C) are functionally dependent in their operations.

(b) The definition contained in Subparagraph (a)(3) of this Rule does not affect the calculation of the allowable emission rate of any indirect heat exchanger permitted prior to April 1, 1999.

(c) Emissions of particulate matter from the combustion of wood shall not exceed:

Allowable Emission Limit

Maximum Heat Input In For Particulate Matter

Million Btu/Hour In lb/Million Btu

Up to and Including 10 0.70

100 0.41

1,000 0.25

10,000 and Greater 0.15

For a heat input between any two consecutive heat inputs stated in the table set forth in this Paragraph, the allowable emissions of particulate matter shall be calculated by the equation E=1.1698*Q-.2230. "E" equals the allowable emission limit for particulate matter in lb/million Btu. "Q" equals the Maximum heat input in million Btu/hour.

(d) This Rule applies to installations in which wood is burned for the primary purpose of producing heat or power by indirect heat transfer.

(e) For the purpose of this Rule, the heat content of wood shall be 8,000 Btu per pound (dry-weight basis). The sum of maximum heat inputs of all wood burning indirect heat exchangers at a plant site that are in operation, under construction, or permitted pursuant to 15A NCAC 02Q, shall be considered as the total heat input for the purpose of determining the allowable emission limit for particulate matter for each wood burning indirect heat exchanger. Wood burning indirect heat exchangers constructed or permitted after February 1, 1983, shall not change the allowable emission limit of any wood burning indirect heat exchanger whose allowable emission limit has previously been set. The removal of a wood burning indirect heat exchanger shall not change the allowable emission limit of any wood burning indirect heat exchanger subject to this Rule whose allowable emission limit has previously been established. However, for any wood burning indirect heat exchanger subject to this Rule constructed after, or in conjunction with, the removal of another wood burning indirect heat exchanger at the plant site, the maximum heat input of the removed wood burning indirect heat exchanger shall no longer be considered in the determination of the allowable emission limit of any wood burning indirect heat exchanger subject to this Rule constructed after or in conjunction with the removal. For facilities or institutions, such as military and educational, whose primary wood burning capacity is for comfort heat, only those wood burning indirect heat exchangers subject to this Rule located in the same power plant or building or otherwise physically interconnected, such as common flues, steam, or power distribution line shall be used to determine the total heat input.

History Note: Authority G.S. 143-213; 143-215.3(a)(1); 143-215.107(a)(5); 143-215.107(h)(1);

Eff. February 1, 1976;

Amended Eff. August 1, 2002; April 1, 1999; June 1, 1985; February 1, 1983;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0505 CONTROL OF PARTICULATES FROM INCINERATORS

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 1987; June 1, 1985; February 1, 1983;

Repealed Eff. October 1, 1991.

15A NCAC 02D .0506 PARTICULATES FROM HOT MIX ASPHALT PLANTS

(a) The allowable emission rate for particulate matter resulting from the operation of a hot mix asphalt plant that are discharged from any stack or chimney into the atmosphere shall not exceed the level calculated with the equation

E = 4.9445(P)0.4376

calculated to three significant figures, for process rates less than 300 tons per hour, where "E" equals the maximum allowable emission rate for particulate matter in pounds per hour and "P" equals the process rate in tons per hour. The allowable emission rate shall be 60.0 pounds per hour for process rates equal to or greater than 300 tons per hour.

(b) Visible emissions from stacks or vents at a hot mix asphalt plant shall not exceed 20 percent opacity when averaged over a six-minute period.

(c) All hot mix asphalt batch plants shall be equipped with a scavenger process dust control system for the drying, conveying, classifying, and mixing equipment. The scavenger process dust control system shall exhaust through a stack or vent and shall be operated and maintained in such a manner as to comply with Paragraphs (a) and (b) of this Rule.

(d) Fugitive non-process dust emissions shall be controlled by 15A NCAC 02D .0540.

(e) Fugitive emissions for sources at a hot mix asphalt plant not covered by Paragraphs (a) through (d) of this Rule shall not exceed 20 percent opacity averaged over six minutes.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. August 1, 2004; July 1, 1998; January 1, 1985;

Readopted Eff. November 1, 2020;

Amended Eff. November 1, 2023.

15A NCAC 02D .0507 PARTICULATES FROM CHEMICAL FERTILIZER MANUFACTURING PLANTS

The allowable emissions rate for particulate matter resulting from the manufacture, mixing, handling, or other operations in the production of chemical fertilizer materials that are discharged from any stack or chimney into the atmosphere shall not exceed the level calculated with the equation E = 9.377(P)0.3067 calculated to three significant figures, where "E" equals the maximum allowable emission rate for particulate matter in pounds per hour and "P" equals the process rate as the sum of the production rate and the recycle rate in tons per hour.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. April 1, 2003; July 1, 1998; January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0508 PARTICULATES FROM PULP AND PAPER MILLS

(a) Emissions of particulate matter from the production of pulp and paper that are discharged from any stack or chimney into the atmosphere shall not exceed:

(1) 3.0 pounds per equivalent ton of air dried pulp from a recovery furnace stack;

(2) 0.6 pounds per equivalent ton of air dried pulp from a dissolving tank vent; and

(3) 0.5 pounds per equivalent ton of air dried pulp from a lime kiln stack.

(b) Emissions from any kraft pulp recovery boiler established after July 1, 1971, shall not exceed an opacity of 35 percent when averaged over a six-minute period. Six-minute averaging periods may exceed 35 percent opacity if:

(1) no six-minute period exceeds 89 percent opacity;

(2) no more than one six-minute period exceeds 35 percent opacity in any one hour; and

(3) no more than four six-minute periods exceed 35 percent opacity in any 24-hour period.

Where the presence of uncombined water vapor is the only reason for failure to meet this opacity limitation, the opacity limitation set forth in this Paragraph shall not apply.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; August 1, 1987; April 1, 1986; January 1, 1985; May 30, 1978;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0509 PARTICULATES FROM MICA OR FELDSPAR PROCESSING PLANTS

(a) The allowable emission rate for particulate matter resulting from the processing of mica or feldspar that are discharged from any chimney, stack, vent, or outlet into the atmosphere shall not exceed the level calculated with the equation E = 4(P)0.677 calculated to three significant figures for process rates less than or equal to 30 tons per hour. For process rates greater than 30 tons per hour but less than 1,000 tons per hour, the allowable emission rate for particulate matter shall not exceed the level calculated with the equation E = 20.421(P)0.1977 calculated to three significant figures. For process rates greater than or equal to 1,000 tons per hour but less than 3,000 tons per hour, the allowable emission rate for particulate matter shall not exceed the level calculated with the equation E = 38.147(P)0.1072 calculated to three significant figures. The allowable emission rate shall be 90.0 pounds per hour for process weight rates equal to or greater than 3,000 tons per hour. For the purpose of these equations, "E" equals the maximum allowable emission rate for particulate matter in pounds per hour and "P" equals the process weight rate in tons per hour.

(b) Fugitive non-process dust emissions shall meet the requirements of 15A NCAC 02D .0540.

(c) The owner or operator of any mica or feldspar plant shall control process-generated emissions:

(1) from crushers with wet suppression, and

(2) from conveyors, screens, and transfer points,

such that the applicable opacity standards in 15A NCAC 02D .0521 or .0524 are not exceeded.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. April 1, 2003; July 1, 1998; April 1, 1986; January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0510 PARTICULATES FROM SAND, GRAVEL, OR CRUSHED STONE OPERATIONS

(a) The owner or operator of a sand, gravel, or crushed stone operation shall not cause, allow, or permit any material to be produced, handled, transported or stockpiled without taking measures, such as application of a dust or wet suppressant, soil stabilizers, covers, or add-on particulate control devices, to reduce to a minimum any particulate matter from becoming airborne to prevent exceeding the ambient air quality standards beyond the property line for particulate matter, both PM10 and total suspended particulates.

(b) Fugitive non-process dust emissions from sand, gravel, or crushed stone operations shall be controlled by 15A NCAC 02D .0540.

(c) The owner or operator of any sand, gravel, or crushed stone operation shall control process-generated emissions:

(1) from crushers with wet suppression; and

(2) from conveyors, screens, and transfer points,

such that the applicable opacity standards in 15A NCAC 02D .0521 or .0524 are not exceeded.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; January 1, 1985;

Readopted. Eff. November 1, 2020.

15A NCAC 02D .0511 PARTICULATES FROM LIGHTWEIGHT AGGREGATE PROCESSES

(a) The owner or operator of a lightweight aggregate process shall not cause, allow, or permit any material to be produced, handled, transported or stockpiled without taking measures, such as wet suppression, to reduce to a minimum any particulate matter from becoming airborne to prevent the ambient air quality standards for particulate matter, both PM10 and total suspended particulates, from being exceeded beyond the property line.

(b) Fugitive non-process dust emissions from lightweight aggregate processes subject to this Rule shall meet the requirement of 15A NCAC 02D .0540.

(c) The owner or operator of any lightweight aggregate process shall control process-generated emissions:

(1) from crushers with wet suppression; and

(2) from conveyors, screens, and transfer points,

such that the applicable opacity standards in 15A NCAC 02D .0521 or .0524 are not exceeded.

(d) Particulate matter from any stack serving any lightweight aggregate kiln or lightweight aggregate dryer shall be reduced by at least 95 percent by weight before being discharged to the atmosphere.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; October 1, 1989; January 1, 1985; April 1, 1977;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0512 PARTICULATES FROM WOOD PRODUCTS FINISHING PLANTS

A person shall not cause, allow, or permit particulate matter caused by the working, sanding, or finishing of wood to be discharged from any stack, vent, or building into the atmosphere without providing, as a minimum for its collection, duct work and collectors that are properly designed and adequate to collect particulate to the maximum extent practicable, or such other devices as approved by the Commission. Commission approval of other devices proposed to meet the requirements of this Rule shall occur on a case-by-case basis. In no case shall the ambient air quality standards be exceeded beyond the property line. Collection efficiency shall be determined on the basis of weight.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0513 PARTICULATES FROM PORTLAND CEMENT PLANTS

(a) Particulate matter from any Portland cement kiln shall:

(1) be reduced by at least 99.7 percent by weight before being discharged to the atmosphere; and

(2) not exceed 0.327 pounds per barrel.

(b) The emissions of particulate matter from any stacks, vent, or outlets from all processes except Portland cement kilns shall be controlled pursuant to 15A NCAC 02D .0515.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0514 PARTICULATES FROM FERROUS JOBBING FOUNDRIES

Particulate emissions from any ferrous jobbing foundry cupola existing before January 2, 1972 shall not exceed:

Maximum Allowable

Process Weight Emission

In lb/hr Rate For Particulate In lb/hr

1,000 3.05

2,000 4.70

3,000 6.35

4,000 8.00

5,000 9.65

6,000 11.30

7,000 12.90

8,000 14.30

9,000 15.50

10,000 16.65

12,000 18.70

16,000 21.60

18,000 23.40

20,000 25.10

Any foundry existing before January 2, 1972, having a capacity greater than shown in the table and any new foundry, regardless of size, shall comply with the particulate emission limits pursuant to 15A NCAC 02D .0515(a).

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 1998; April 1, 1986; January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0515 PARTICULATES FROM MISCELLANEOUS INDUSTRIAL PROCESSES

(a) The allowable emission rates for particulate matter from any stack, vent, or outlet, resulting from any industrial process for which no other emission control standards are applicable, shall not exceed the level calculated with the equation E = 4.10(P)0.67 calculated to three significant figures for process rates less than or equal to 30 tons per hour. For process rates greater than 30 tons per hour, the allowable emission rates for particulate matter shall not exceed the level calculated with the equation E = 55.0(P)0.11- 40 calculated to three significant figures. For the purpose of these equations "E" equals the maximum allowable emission rate for particulate matter in pounds per hour and "P" equals the process rate in tons per hour.

(b) Process rate means the total weight of all materials introduced into any specific process that may cause any emission of particulate matter. Solid fuels charged are considered as part of the process weight, but liquid and gaseous fuels and combustion air are not. For a cyclical or batch operation, the process rate is derived by dividing the total process weight by the number of hours in one complete operation from the beginning of any given process to the completion thereof, excluding any time during which the equipment is idle. For a continuous operation, the process rate is derived by dividing the process weight for a typical period of time by the number of hours in that typical period of time.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. April 1, 2003; July 1, 1998; January 1, 1985; December 1, 1976;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0516 SULFUR DIOXIDE EMISSIONS FROM COMBUSTION SOURCES

(a) Emissions of sulfur dioxide from any source of combustion, including air pollution control devices, discharged from any vent, stack, chimney, or flare shall not exceed 2.3 pounds of sulfur dioxide per million Btu input.

(b) When determining compliance with this standard:

(1) the sulfur dioxide formed by the combustion of sulfur in fuels, wastes, ores, and other substances shall be included;

(2) the sulfur dioxide formed or reduced as a result of treating flue gases with sulfur trioxide or other materials shall be included in the computation of emissions; and

(3) the determination of Btu input shall not include the contribution from any portion of fuels used exclusively to inflate the heat input value used to demonstrate compliance with the emission standard in Paragraph (a) of this Rule.

(c) The standard set forth in Paragraph (a) of this Rule shall not apply to sulfur dioxide emission sources already subject to an emission standard for sulfur dioxide in 15A NCAC 02D .0524, .0527, .1110, .1111, .1206, or .1210.

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 2007; April 1, 2003; July 1, 1996; February 1, 1995; October 1, 1989; January 1, 1985; April 1, 1977;

Readopted Eff. November 1, 2020;

Amended Eff. June 1, 2023.

15A NCAC 02D .0517 EMISSIONS FROM PLANTS PRODUCING SULFURIC ACID

Emissions of sulfur dioxide or sulfuric acid mist from the manufacture of sulfuric acid shall not exceed:

(1) 27 pounds of sulfur dioxide per ton of sulfuric acid produced; and

(2) 0.5 pounds of acid mist, expressed as sulfuric acid, per ton of sulfuric acid produced.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0518 MISCELLANEOUS VOLATILE ORGANIC COMPOUND EMISSIONS

History Note: Authority G.S. 143-215.3(a)(1); 143-215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. April 1, 1997; July 1, 1996; September 1, 1994; December 1, 1993; February 1, 1993;

Repealed Eff. July 1, 2000.

15A NCAC 02D .0519 CONTROL OF NITROGEN DIOXIDE AND NITROGEN OXIDES EMISSIONS

(a) The emissions of nitrogen dioxide shall not exceed 5.8 pounds per ton of acid produced from any nitric acid manufacturing plant.

(b) The emissions of nitrogen oxides shall not exceed:

(1) 0.8 pounds per million BTU of heat input from any oil or gas‑fired boiler with a capacity of 250 million BTU per hour or more; or

(2) 1.8 pounds per million BTU of heat input from any coal‑fired boiler with a capacity of 250 million BTU per hour or more.

(c) The emission limit for a boiler burning coal, oil, or gas in combination shall be calculated by the equation:

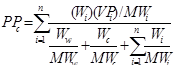

![]()

(1) E = the emission limit for combination in pounds per million BTU.

(2) Ec = emission limit for coal only as determined by Paragraph (b) of this Rule in pounds per million BTU.

(3) Eo = emission limit for oil or gas as determined by Paragraph (b) of this Rule in pounds per million BTU.

(4) Qc = the actual coal heat input to the combination in BTU per hour.

(5) Qo = the actual oil and gas heat input to the combination in BTU per hour.

(6) Qt = Qc + Qo and is the actual total heat input to the combination in BTU per hour.

(d) If a boiler is subject to an emission standard for nitrogen oxides pursuant to 15A NCAC 02D .0524 or 15A NCAC 02D .1418, then the boiler shall meet the standard in that particular rule instead of the standard in Paragraph (b) of this Rule.

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. July 1, 2007; January 1, 2005; July 1, 1996; October 1, 1989; January 1, 1985;

Readopted Eff. November 1, 2020.

15A NCAC 02D .0520 CONTROL AND PROHIBITION OF OPEN BURNING

History Note: Authority G.S. 143‑215.3(a)(1); 143‑215.107(a)(5);

Eff. February 1, 1976;

Amended Eff. January 1, 1985; November 1, 1978; December 1, 1976;

Repealed Eff. July 1, 1996.

15A NCAC 02D .0521 CONTROL OF VISIBLE EMISSIONS

(a) Purpose. The intent of this Rule is to prevent, abate, and control emissions generated from fuel burning operations and industrial processes where an emission can be expected to occur, except during startups, shutdowns, and malfunctions approved according to procedures in 15A NCAC 02D .0535.

(b) Scope. This Rule shall apply to all fuel burning sources and to other industrial processes having a visible emission. Sources subject to a specific visible emission standard in 15A NCAC 02D .0506, .0508, .0524, .1110, .1111, .1206, or .1210 shall meet that standard instead of the standard contained in this Rule. This Rule does not apply to engine maintenance, rebuild, and testing activities where controls are infeasible, but it does apply to the testing of peak shaving and emergency generators. In deciding if controls are infeasible, the Director shall consider emissions, capital cost of compliance, annual incremental compliance cost, and environmental and health impacts.